Frequently Asked Questions

1. How does someone identify their Power Wheel® part number?

2. What kind of oil should I put in my Power Wheel® planetary drive?

Power Wheel Planetary Drives are shipped without lubricant and must be filled to the proper level prior to start-up.

1. Type

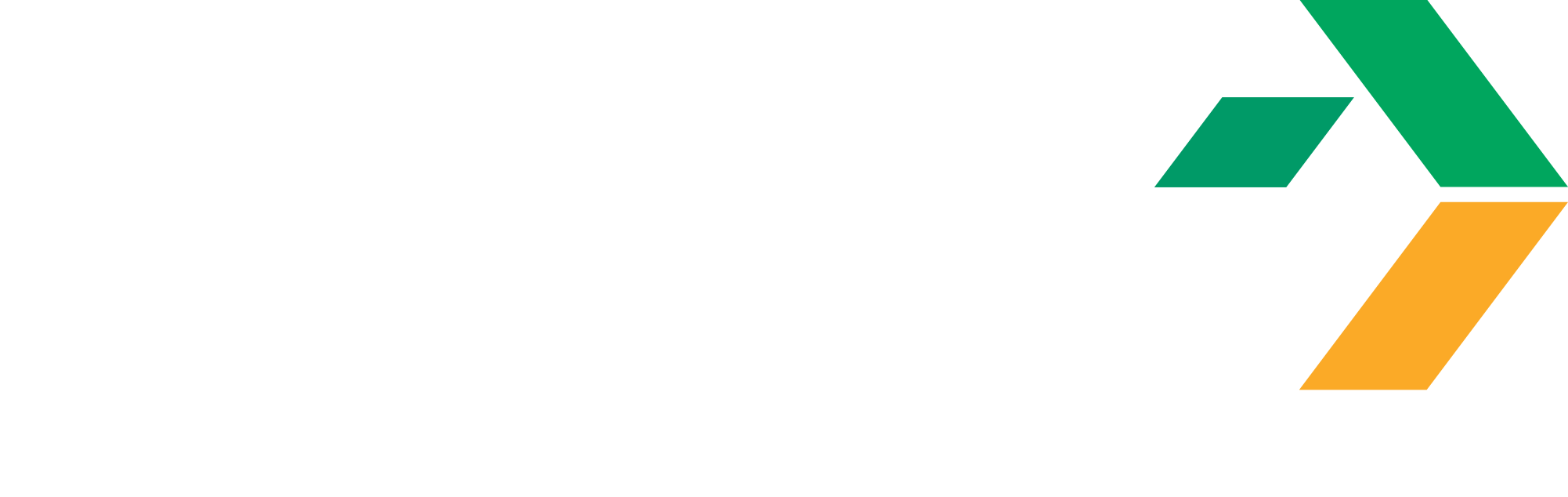

In normal applications use an extreme pressure lubricant API-GL-5 approved. AGI recommends SAE 80W, 90, 80W-90 and 85W-90 grades of lube under normal climate and operating conditions. See chart below. For severe or abnormal applications with special requirments consult either Auburn Gear or a lubricant manufacturer for further assistance.

2. Change Interval

Initial lubrication change after 50 hours of operation. Subsequent changes every 1000 hours or yearly whichever comes first.

3. Lube Temperature

Continuous operating temperatures of 160℉ are allowable. Maximum intermittent temperature recommended is 200℉.

4. Amount of Lube

The unit should be half full when mounted horizontal. Lube level for other mounts will vary. Consult Auburn Gear for details.

5. Shaft Spindle Up Mounting

If mounting unit vertically with shaft or spindle up, special provisions apply to ensure adequate lubrication of output bearings. Consult Auburn Gear.

* Maximum temperature for Brookfield Viscosity of 150,000centipoise(cP)2 per SAE J306 MAR85

1 Brookfield Viscosity – apparent viscosity as determined under ASTM D 2983

2 150,000 cP determined to provide sufficient low temperature lube properties for Auburn Gear Power Wheels

All Power Wheels® are compatible with synthetic lubricants as long as they meet the above specified Parameters.

3. How much oil should I put in my Power Wheel® planetary drive?

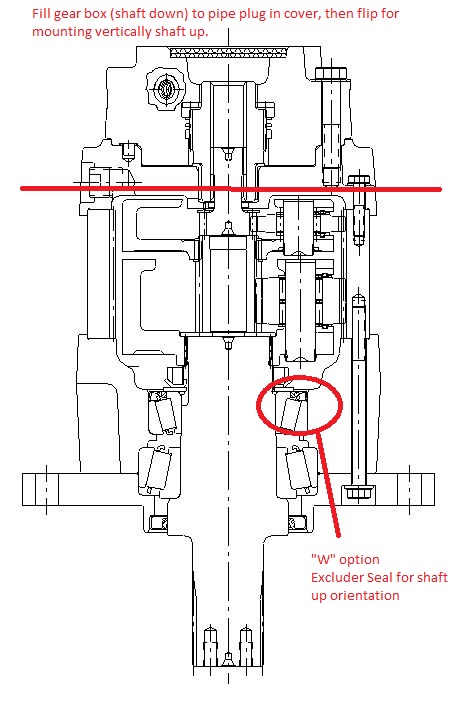

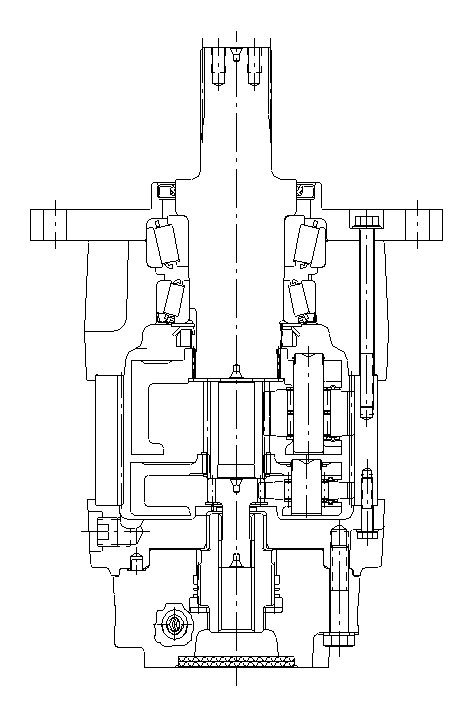

Mounted Vertically Shaft Up

Lastly, if mounted vertically shaft up. In certain models, a “W” option is available and this option allows the bearings to be greased for vertical operation. If this option is not available a stand pipe option would need to be considered so the bearings can be adequately lubricated. If an A2 Series brake is selected for a shaft up application, a wet brake should be selected as the gearbox and brake will share the same oil sump. Fill the oil to the cover plug, once filled then flip for vertical shaft up application.

4. Can I purchase direct from Auburn Gear?

If you are an OEM, Original Equipment Manufacturer, please contact us and we will determine the best means to service your requirements. If you are an end user in search of service or repairs components, please contact your authorized Auburn Gear Power Wheel distributor.

Mounted Horizontally

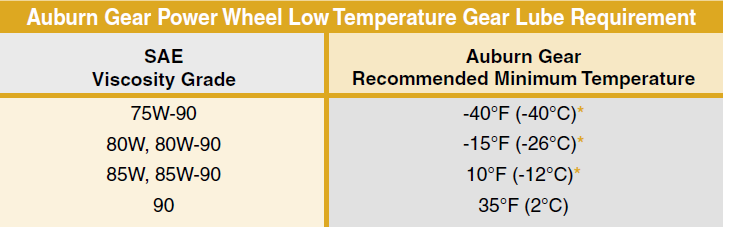

If mounted horizontally, the drive should be filled ½ full of the recommended oil. If the unit is mounted vertically, other factors must be considered. If mounted vertically and the output shaft is pointed toward the ground, one must be able to see oil at the highest mesh point.

Mounted Vertically

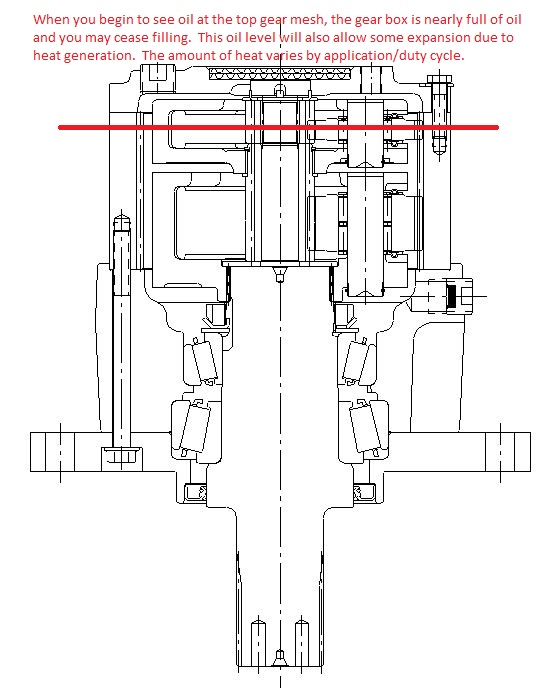

If mounted vertically, again, shaft down and an A2 Series brake has been selected. First of all, a dry brake must be specified if the unit is mounted vertically shaft down (Dry brakes begin with a “V” designation). Fill the unit with oil,until oil runs out of the 1/2” pipe plug on the cover.

Mounted Vertically Shaft Up

Lastly, if mounted vertically shaft up. In certain models, a “W” option is available and this option allows the bearings to be greased for vertical operation. If this option is not available a stand pipe option would need to be considered so the bearings can be adequately lubricated. If an A2 Series brake is selected for a shaft up application, a wet brake should be selected as the gearbox and brake will share the same oil sump. Fill the oil to the cover plug, once filled then flip for vertical shaft up application.

4. Can I purchase direct from Auburn Gear?

If you are an OEM, Original Equipment Manufacturer, please contact us and we will determine the best means to service your requirements. If you are an end user in search of service or repairs components, please contact your authorized Auburn Gear Power Wheel distributor.