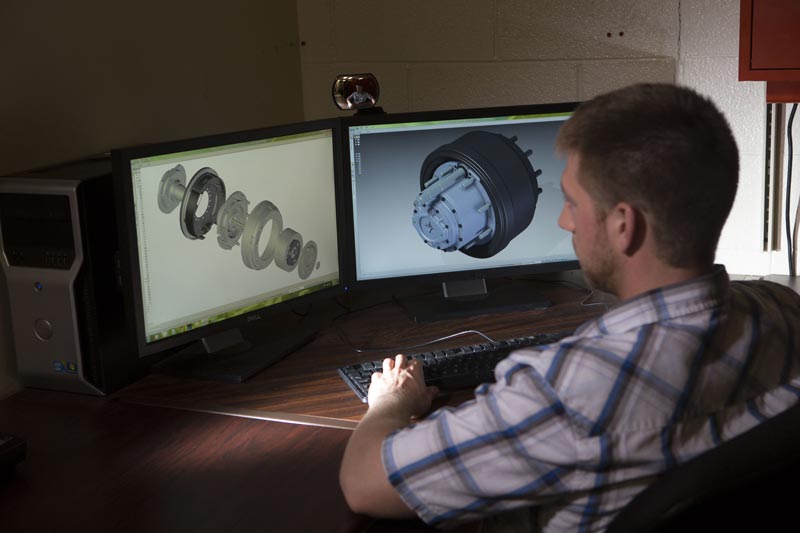

Engineering

Design & Product Development

Solid Edge 3D CAD system

Solid Edge 3D CAD system- APQP New Product Release Process with Phase Gates

- Design for Manufacturing

- Prototyping capabilities

- Spline & Gear design

- FMEA

- DVP&R

- Provide 3D models & dimensional Installation Drawings for customers

- Support creation of service manuals

Analysis & Application Calculations

- Full FEA capability based on Solid Edge software

- Power Gear gear design program, AGMA based

- Gear life calculations based on duty cycles

- Application analysis

- Bearing life calculations

- Tolerance Stack-ups & clearance / fit analysis

- Failure analysis

- FEA data correlation with lab / field testing

Product Engineering Test Lab Capabilities

Lima-Baldwin

Capacity:

600,000 lb-in torque

Purpose:

Ultimate Torsional Loading

Strain gage Calibration

Benefit to Customer:

Material analysis tool (Product Integrity)

Insure measured actual application loads correlate with lab loading (Technical Competence)

Material Testing System (MTS)

Capabilities:

100,000 lbs of force

Programmable

Two Step Loading

Purpose:

Tensile or compressive loading

Torsional loading

Fatigue testing

Benefit to Customer:

Historical testing information

A means of comparison which helps to determine product ratings and life

Hydrostatic Dynamometer

Capacity:

Capacity:

110 HP

240,000 lb-in Torque cell (output torque)

4500 PSI Hydraulic System

Purpose:

Product Development

Duty Cycle (Wear Characteristics)

Rotary Gear Fatigue

Ability:

Duty cycle Programmable to match data obtained from strain gaged field tests.

When loaded, generates up to 70% of its own electricity

Benefits to Customer:

Enables Auburn Gear to properly develop and rate our products (Product Integrity)

In-Line dynamometer

Capacity:

150 HP Prime Mover

200,000 lb-in Torque cell (output torque)

Purpose:

Rotary Gear Fatigue

Thermal Horsepower

Speed/Torque vs. Temperature Ability:

Duty cycle programmable to match data obtained from strain gaged fieldtests

Benefit to Customer:

Enables Auburn Gear to properly rate our products (Product Integrity)

E-Trac (Electric Drive) Dynamometer

Capacity:

30 HP Absorber

Prime Mover determined from application

10,000 lb-in Torque cell (output torque)

Purpose:

Rotary Gear Fatigue

Thermal Horsepower

Speed/Torque vs. Temperature

System Integration / CAN communication

Ability:

Duty cycle programmable to match data obtained from strain gaged field tests

When loaded, generates up to 70% of its own electricity

Benefit to Customer:

Enables Auburn Gear to properly rate our products (Product Integrity)

System Integration / Fault Detection to help customers with integration into their chassis and replicate electrical / CAN issues

Axle Dynamometer

Capacity:

125 HP Prime Mover

96,000 lb-in Torque cell (output torque)

Purpose:

Differential Gear fatigue

Differential Case Fatigue

Differential Bias

Oil & wear Evaluations

Hypoid Gear Fatigue

Benefit to Customer:

A rating and life prediction tool (Product Integrity)

Shaft-Out Style Power Wheel Bearing Test Stand

Capabilities:

Variable Input RPM

Programmable Axial Loading

Purpose:

Determine/Verify Bearing ratings

Benefit to Customer:

Enables Auburn Gear to properly rate our products (Product Integrity)

Wheel Drive Style Power Wheel Bearing Test Stand

Capabilities:

Variable Input RPM

Constant Radial Loading

Programmable Axial Loading

Purpose:

Determine / Verify Bearing ratings

Benefit to Customer:

Enables Auburn Gear to properly rate our products (Product Integrity)

Inertia Dynamometer

Capabilities:

Ability to apply .22 km2 to 10 km2 at a variable RPM to obtain a desired moment of Inertia.

Purpose:

Qualify and rate brake parts.

Impact testing of internal gearing.

Benefit to Customer:

A rating and life prediction tool (Product Integrity)

Reeves Veri-drive

Capabilities:

5 HP Prime Mover

Variable input RPM

Purpose:

Hot and cold Seal testing

Unit heat generation

Noise level

Various specialized testing

Benefit to Customer:

A rating and life prediction tool (Product Integrity)

1995 Chevrolet Camaro Z28

Purpose:

Field testing for development and test of Hi-Performance and ECTED Differentials

Soap Trough testing

Benefit to Customer:

A rating and life prediction tool (Product Integrity)

1997 Jeep Wrangler

Purpose:

Field testing of 4 wheel drive and off road Hi-Performance and ECTED Differentials

Benefit to Customer:

A rating and life prediction tool (Product Integrity)

Data Acquisition System

Capabilities:

Simultaneously collect data on 32 channels

Will collect data in excess of 80,000 samples/second

Replay and manipulate data into charts & graphs

Purpose:

Collect and store data from actual field testing in dynamic or static conditions (i.e. torque, pressure, temperatures, etc)

Benefit to Customer:

Analysis of data collected from specific field applications.

Collected data used to develop application specific duty cycles for lab testing.

Assures Product integrity per application

Strain Gage System

Purpose:

Measure surface strain and torque on engineered components

Strains and torques can be converted into engineering units for collection by data acquisition

Benefit to customer:

Enables Auburn Gear to determine loads on components (Helps to assure Product Integrity)

Heat Treatment

AG LLC operates its own captive heat treat department and has in house capabilities of processing nearly all of our material and gearing heat treatment requirements.

In house process capabilities include:

Batch furnace processing for:

Carburizing & Oil quench

Carbonitriding & Oil quench

Neutral hardening & Oil quench

Atmosphere quenching

Selective case hardening

Batch tempering

Induction hardening with continuous furnace tempering

Atmosphere Heat Treat Processing Equipment

One 36 – 48 – 36 integral quench batch furnace with top cool capabilities

One 36 – 48 – 36 integral quench batch furnace

One 20 – 36 – 24 integral quench batch furnace

Two 36 – 48 batch temper furnaces

One 24 – 36 batch temper furnace

Endothermic gas atmosphere generators

Nitrogen furnace purge / atmosphere

Auxiliary Processing Equipment

Shot peening

Abrasive grit blast cleaning

Straightening

Metallurgical Testing and Inspection

Complete metallurgical laboratory on site fully equipped for material analysis for process control of heat-treat department, material characterization and failure analysis.

Hardness testing

Brinell

Rockwell

Knoop

Metallograghic inspection

Charpy Impact testing

Rotating Bending Fatigue testing

Non Destructive testing

Magnetic Particle Inspection

Ultrasonic Inspection

Optical / visual inspection low magnification (10 – 25 X)

Quality Assurance

AG is ISO 9001:2008 registered and maintains a Quality Management System that supports engineering planning & design, manufacturing process control and continual improvement of our products and services.

QA Personnel

Auburn Gear has a fully staffed Quality assurance and Inspection operation

- 3 shift coverage to support manufacturing

- 2 Certified Quality Engineers

- One certified level II NDT inspector in MP

- One certified level III NDT inspector in MP

- All personnel are cross-trained in the myriad of our Inspection Lab processes

Quality inspection Systems

The Quality Assurance department and Gage Lab is an ISO compliant department and utilizes work instructions and procedures to document and insure consistent inspection of our products manufactured on site and purchased.

- First Article verification of all features of new or revised parts.

- Set-up approval for every work order before the parts are manufactured.

- All processes are documented for consistent results.

- Quality Engineering supports Manufacturing as well as the Engineering Department with Engineering Lab checks as well as special checks for Manufacturing Engineering.

- Non-conforming material is quarantined and reviewed daily for disposition

- Processes – Quality department personnel make use of computer-based processes to support Manufacturing and Engineering.

- Mini-Tab Statistical Analysis software.

- Gage Calibration is maintained in the business software system for accountability and consistently performing inspection equipment.

- Capability Studies are performed periodically per customer request and for manufacturing process surveillance.

- Support Engineering as an in-house Geometric Dimensioning and Tolerancing consultant.

Metrology

Inspection Equipment

Auburn Gear has state of the art CMM capabilities as well as hand held inspection devices and process specific gages. AG utilizes in house capability to design and provide specialized gages for the most demanding process control.

- Gleason M&M Gear Checker

- Zeiss Eclipse Coordinate Measuring Machine

- Zeiss Accura II Coordinate Measuring Machine

- Gage Master Optical Comparator

- Fellows Red Liner Gear Checker

- Micro-Hite Electronic Height Gage

- Full complement of hand held gages and equipment such as calipers, micrometers, Surface Finish checkers, and surface plates for dimensional layout.

- Part / feature specific inspection and testing gages.

Auburn Gear Manufacturing Capabilities

(2) Gleason CNC Vertical Hobbing Machines 1998 & 2012

Cylindrical Gear hobbing with Internal Bore Clamping

Maximum Diametral Pitch 8.50

Maximum outside Diameter 5.118”

Automated loading for unattended operation

(2) CNC Horizontal Hobbing Machines

For shaft work

Retrofitted Barber Colman 14-15 with CNC Controls

Outside Diameter clamping with tail stock center support

(12) Horizontal Barber Colman Hobbing Machines

(2) with Double Cut capabilities

(2) with Long Bed Capacity

(6) Shave Machines

For shaving of spur gears with crowning capabilities

Internal Spline and Gear Broaching

– Horizontal and Vertical machines

– Machine capacity of 50 tons with 90” Stroke, Vertical Table Up

Internal and External Shaper Cutting of Splines and Gears

(9) Fellows Shaper Machines

(4) with CNC controls with slotting and sector cutting capabilities

(2) with Tailstock for shaft work

(1) with 9” raise new in 2014

– 20” Maximum Diameter, with 8” face width, 3.0 Diameteral Pitch

Straight Bevel Gear Cutting and Roll Testing

Gleason Revacycle ® and Coniflex ® Machines

(6) 4-axis lathes, Cincinnati and Mazak

– Capable of simultaneous internal and external machining

Phosphate Coating Line (lubrite)

Assembly and testing of Differentials

Load Monitoring for Torque Bias

PLC Controlled for testing in forward and reverse directions

Engage and disengage coil for ECTED

Mori Seiki NT-4300 Mill-Turn Center (4)

– (3) with Full contouring B-axis – 2013 & 2015

– (1) with B-axis indexing of 1 degree – 2012

– (9) programmable axes

– Both Main and Sub-Spindles 40 HP

– 28.7″ swing

– 100 Tool Magazine

– 20 Tool Lower Turret

– In Machine Measuring Device

Renishaw probe used to locate features on a part or casting with ability to orientate any necessary machining from the originally located feature

(1) Robot with 150 pound part capacity and end of arm tool changer to load and unload two machines

(1) Robot with 250 pound part capacity and end of arm tool changer to load and unload two machines with integrated vision system

Capable of turning, milling, Drilling, tapping parts complete in one setup

Gear and spline generating capabilities up to 2.0 Diameteral Pitch

2-axis Lathes

Steel and Cast Iron Turning

ID Collet Chucks

OD Collet Chucks

Tail Stock Supports

3-Jaw Chucks up to 15”

(4) with Live Tooling

(6) Motch Vertical CNC Chucker Lathes

Large part, approx. 24” OD and ID Turning

Upgraded with Fanuc 0-i series control in 2011

Vertical Machining Centers

Thru Spindle Coolant

CAT 40 and CAT 50 Spindles

(2) with Full Contouring 4-axis

(1) with 4th axis indexer .001 Degree accuracy

(1) Pallet Changer

(1) High Pressure Coolant for Deep hole drilling

Hardturn Capabilities on 2-axis and 4-axis Lathes Software

– ESPRIT CAM software used for programming

– Solid Edge CAD software

Mori Seiki NL-2500 Turning Centers (2)

Sub-spindle

Live Tooling

Y-Axis

High Pressure Coolant

In Machine Gear and Spline generating ability

(1) With Bar Feeder

Capacity up to 3.1”

Shafts up to 24” length

Shaft unloader table thru sub-spindle

Both Main and Sub-Spindle OD Collet Chucks

Unattended operation utilizing parts catcher

(1) With Robot

3-jaw chuck with 10” capacity

ID Collet Chuck on Sub-spindle

Robot Load and Unload capable of handling parts up to 40 pounds

Grinding

I.D. Grinding

O.D. Grinding

- Profile Cam

- Plunge

- Center-less

- Blanchard

CNC I.D. Grinding

- Robot Load and Unload

- Integrated Gaging with feedback loop back to CNC to control size

(4) Assembly Lines for planetary wheel drives

PLC Controlled presses to set bearing pre-load while rotating the unit to achieve unmatched precision and consistency.

PLC controlled end of line testers used to drive the wheel thru the input of planetary in both the forward and reverse directions, while using air to check for any potential oil leaks.

For units equipped with integrated parking brake, the break is released during the spin test and held in position to detect any leak down.