Swing Drives

Swing Drives are an important and integral segment of our Power Wheel® planetary gear drive product line.

The standard Swing Drives utilize integral pinion gears with a bearing-nut shaft retention device to provide reliable shaft retention and precise bearing preload. All Swing Drives are also built with high-capacity tapered roller bearings. We offer several Model sizes with a variety of pinion configurations and multiple hub/flange mounting configurations. Let Auburn Gear help you find the most reliable and economic solution to your Swing Drive needs.

All swing drives require—at the very least—a static parking brake for transport purposes. However, in some applications, a static and dynamic brake is required. Auburn Gear can provide either requirement per customer request. If you run across a swing drive application that would benefit from an Auburn Gear custom solution, please contact us today.

Swing Drive Applications

- Aerial work platforms

- Construction cranes

- Utility bucket booms

- Excavators

- Rack drives

- Grapples

- Fire trucks

- Forestry equipment

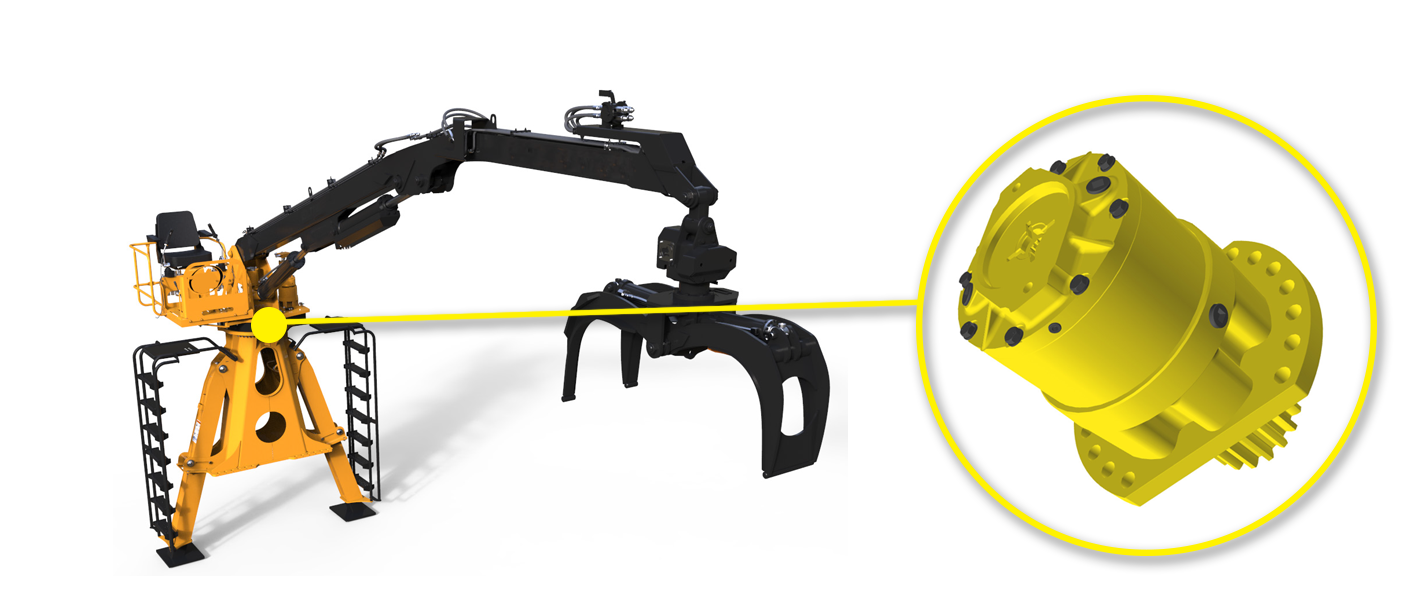

Application Spotlight

FORESTRY GRAPPLE FEATURING POWER WHEEL® MODEL 7 SWING DRIVE

This application highlights a Model 7 Swing Drive for a log loader or forestry grapple. In the Model 6 and 7 Swing Drive product line, Auburn Gear manufactures over ten (10) different hub configurations. In this specific application, the hub configuration is a SW5.

This customer required an output pinion gear; however, a splined shaft can be provided as well, if the customer prefers a bolt on pinion gear.

All Auburn Gear output pinion gears are manufactured in-house. They are either shaper cut, hobbed, or invo-milled on our 5-axis Mori Seiki NTs. Auburn Gear was the first manufacturer to develop the invo-milling process in conjunction with Mori Seiki. This manufacturing flexibility provided by Auburn Gear eliminates the need for additional tooling based on a new gear summary requirement.

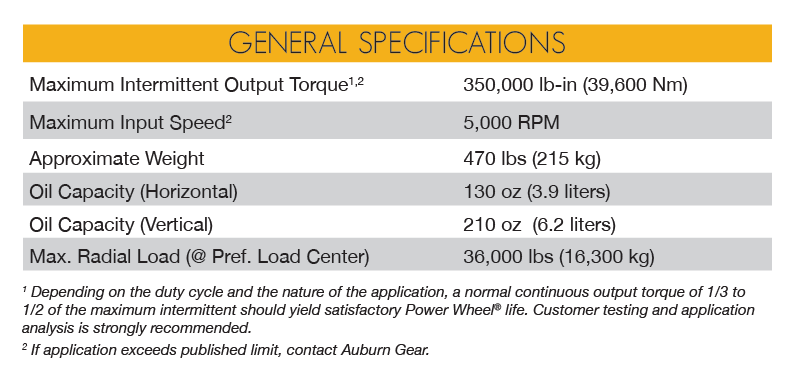

| Model | Maximum Intermittent Output Torque | Maximum Input Speeds (RPM) | Maximum Radial Load Capacity | Ratios | ||

| lbf-in | N-m | lbf | kgf | |||

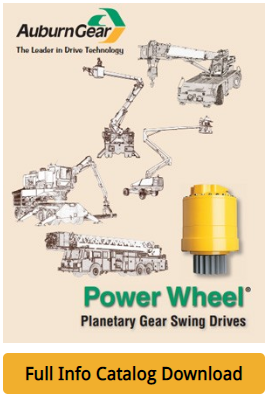

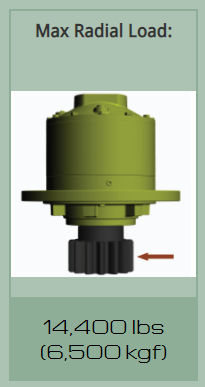

| 6 | 50,000 | 5,700 | 3,500/5,000 | 14,400 | 6,500 | 3.75 – 33.79:1 |

| 7 | 70,000 | 7,900 | 3,500/5,000 | 14,400 | 6,500 | 3.75 – 33.79:1 |

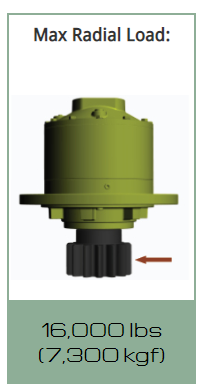

| 8 | 100,000 | 11,300 | 3,500/5,000 | 16,000 | 7,300 | 3.92 – 1064.39:1 |

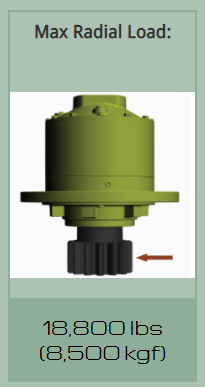

| 8B | 100,000 | 11,300 | 3,500/5,000 | 18,800 | 8,500 | 3.92 – 1064.39:1 |

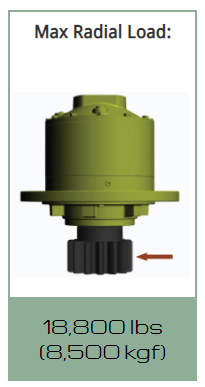

| 9 | 130,000 | 14,700 | 3,500/5,000 | 18,800 | 8,500 | 3.92 – 1064.39:1 |

| 9 Plus | 130,000 | 14,700 | 3,500/5,000 | 30,000 | 13,600 | 3.92 – 1064.39:1 |

| 145 | 145,000 | 16,400 | 3,500/5,000 | 23,100 | 10,500 | 3.92 – 1064.39:1 |

| 10 | 180,000 | 20,300 | 3,500/5,000 | 30,000 | 13,600 | 4.22 – 52.35:1 |

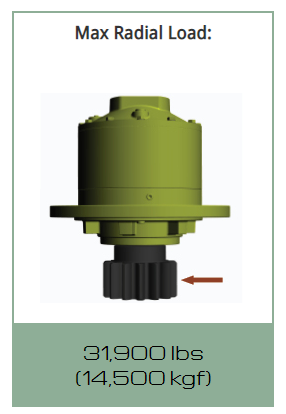

| 200 | 200,000 | 22,600 | 5,000 | 31,900 | 14,500 | 27.18 – 52.35:1 |

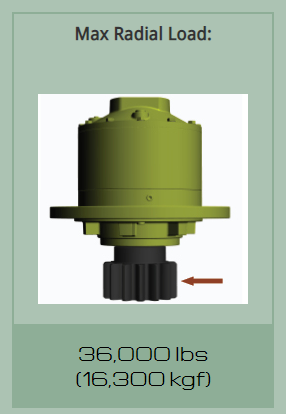

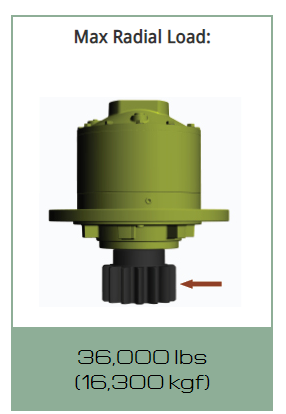

| 250 | 250,000 | 28,300 | 4,000 | 36,000 | 16,300 | 20.52 – 46.00:1 |

| 350 | 350,000 | 39,600 | 4,000 | 36,000 | 16,300 | 20.52 – 46.00:1 |

* 3500 rpm maximum for single reductions REDUCED BACKLASH Swing Drives

Some swing drive applications are used strictly for positional location as opposed to a high-frequency cycle of continuous reverse rotations as in many common swing drive applications, like excavators or various loaders. For those applications that only require a more precise positional location capability, Auburn Gear’s reduced backlash units can minimize boom sway or movement. Reduced backlash units are available for all Power Wheel® Swing Drive Models. Contact us today.

Model 6 Swing Drives

Features:

Additional Performance Data

Additional Performance Data

Max Continuous Torque – 25,000 lbf-in (2,800 N-m)

Max Input Speed – 3,500 rpm (single reduction)

– 5,000 rpm (double reduction)

Ratio Range – 3.75 to 33.79:1

Hydraulic Motor Mountings – SAE A, B & C

Model 7 Swing Drives

Features:

Additional Performance Data

Additional Performance Data

Max Continuous Torque – 35,000 lbf-in (4,000 N-m)

Max Input Speed – 3,500 rpm (single reduction)

– 5,000 rpm (double reduction)

Ratio Range – 3.75 to 33.79:1

Hydraulic Motor Mountings – SAE A, B & C

Model 8 Swing Drives

Features:

Additional Performance Data

Additional Performance Data

Max Continuous Torque – 50,000 lbf-in (5,700 N-m)

Max Input Speed – 3,500 rpm (single reduction)

– 5,000 rpm (all other reductions)

Ratio Range – 3.92 to 50.00:1 Triple Reductions from 70.61 to 183.02:1 Quadruple Reductions from 264.75 to 1064.39:1

Hydraulic Motor Mountings – SAE A, B, C, & D

Model 8B Swing Drives

Features:

Additional Performance Data

Additional Performance Data

Max Continuous Torque – 50,000 lbf-in (5,700 N-m)

Max Input Speed – 3,500 rpm (single reduction)

– 5,000 rpm (al other reductions)

Ratio Range – 3.92 to 50.00:1 Triple Reductions from 70.61 to 183.02:1 Quadruple Reductions from 264.75 to 1064.39:1

Hydraulic Motor Mountings – SAE A, B, C, & D

Model 9 Swing Drives

Features:

Additional Performance Data

Additional Performance Data

Max Continuous Torque – 65,000 lbf-in (7,400 N-m)

Max Input Speed – 3,500 rpm (single reduction)

– 5,000 rpm (double reduction)

Ratio Range – 3.92 to 50.00:1 Triple Reductions from 70.61 to 183.02:1 Quadruple Reductions from 264.75 to 1064.39:1

Hydraulic Motor Mountings – SAE A, B, C, & D

Model 9 plus Swing Drives

Features:

Additional Performance Data

Additional Performance Data

Max Continuous Torque – 65,000 lbf-in (7,400 N-m)

Max Input Speed – 3,500 rpm (single reduction)

– 5,000 rpm (all other reductions)

Ratio Range – 3.92 to 50.00:1 Triple Reductions from 70.61 to 183.02:1 Quadruple Reductions from 264.75 to 1064.39:1

Hydraulic Motor Mountings – SAE A, B, C, & D

Model 145 Swing Drives

Features:

Additional Performance Data

Additional Performance Data

Max Continuous Torque – 72,500 lbf-in (8,200 N-m)

Max Input Speed – 3,500 rpm (single reduction)

– 5,000 rpm (all other reductions)

Ratio Range – 5.50 to 50.00:1 Triple Reductions from 118.13 to 183.02:1 Quadruple Reductions from 442.89 to 1064.39:1

Hydraulic Motor Mountings – SAE A, B, C, & D

Model 10 Swing Drives

Features:

Max Continuous Torque – 90,000 lbf-in (10,200 N-m)

Max Continuous Torque – 90,000 lbf-in (10,200 N-m)

Max Input Speed – 3,500 rpm (single reduction)

– 5,000 rpm (double reduction)

Ratio Range – 4.96 to 52.35:1

Hydraulic Motor Mountings – SAE A, B, C, & D

Model 200 Swing Drives

Features:

Additional Performance Data

Additional Performance Data

Max Continuous Torque – 100,000 lbf-in (11,300 N-m)

Max Input Speed – 5,000 rpm (double reduction)

Ratio Range – 27.18 to 52.35:1

Hydraulic Motor Mountings – SAE A, B, C, & D

Model 250 Swing Drives

Features:

Additional Performance Data

Additional Performance Data

Max Continuous Torque – 125,000 lbf-in (14,200 N-m)

Max Input Speed – 4,000 rpm (double reduction)

Ratio Range – 20.52 to 46.00:1

Hydraulic Motor Mountings – SAE C & D